Driving commercial expansion at pharma companies

As pharma start-ups mature from R&D organisations into commercial ventures, they need to establish governance, controls and disciplines across their operations. John Mason, Manufacturing & Engineering Services Partner at Curzon Consulting explores market expansion and operating model maturity.

Market expansion

Pharma companies should deploy a scalable and repeatable go-to-market approach to guide, accelerate and assure commercial expansion.

The benefits are:

- Identify, manage and reduce operational, commercial and regulatory risk

- Independent review and challenge of expansion plans and strategies

- Decrease duplication, rework and capability gaps

Operating model maturity

Reduce compliance and performance risks through improved governance, controls and disciplines across the footprint. The benefits include:

- Clarity on investment priorities

- Standardised, effective and efficient ways of working

- Rapid deployment of back office services

- Simplified data and systems landscapes

Programme management

Deploy robust disciplines, tools and capabilities to drive efficient and effective commercial expansion programme. The benefits are:

- Balance agile ways of working with quality, discipline and challenge to optimise outcomes

- Access tried and tested programme management toolkit and capabilities

- Grow organisational skills and capabilities

Contact us to explore how to drive market expansion and operating model maturity.

Want to find out how our Industry & Energy Services consulting team can help?

Re-assessing cost after COVID-19

The global COVID-19 pandemic has provoked the need for businesses to re-assess their footprint and cost base across the supply chain. John Mason, Manufacturing & Engineering Services Partner at Curzon Consulting, considers the case for structural change.

Re-assessing cost after COVID-19

The COVID-19 crisis has altered the landscape for many. Some have already acted to reduce staff numbers and consolidate operations as an initial response to falling revenues. Structural change and a lower cost base may be required to adapt for the longer term driven by:

- Altered demand volumes, market location and mix of products and services as markets and the customer base evolves

- New regimes to protect health and wellbeing that change how people can work

- The increasing de-globalisation trend, prompting a re-think on the resilience of supply chains and moves to localise

The scenarios and options for each business will be different and the ‘best fit’ answer will not necessarily be obvious.

Considering the case for structural change

Supply-side capacity

- What capacity is needed now and for the medium term? Can excess capacity be re-purposed to meet expected new demand or is consolidation possible?

- Restructuring the footprint is an opportunity to deliver a step change in the cost base and renewed focal points for future investments

Network view

- How fit for purpose are existing facilities now? Can a more cost-effective and resilient model be found by looking at the network as a whole?

- Potential changes to both demand and supply-side environments will impact the economics of the current model and an holistic view is needed

Supply chain

- Will customers demand more localised sourcing to reduce interruption risk in their business-critical supply chains? Is a pre-emptive move to adapt the footprint more attractive than a reactive one?

- Sourcing and certifying new suppliers may be a critical dependency for re-locating production. It is also an opportunity to re-think make-buy strategies, secure new capabilities, strengthen key supplier relationships and unlock cost savings

Overhead right size

- What opportunities from changed working practices should now be evolved to deliver a lower overhead cost model?

- Remote working, greater comfort with and reliance on technology, and demonstrated operation with reduced indirect staffing levels creates new baselines for the operating model

Digital evolution

- What opportunities are created through a reshaping of the footprint to accelerate adoption of digital technologies?

- Relocation of capabilities to be better aligned with future demand will require assessment of products, processes, assets, resources and technology infrastructure. Introduction of technology to deliver cost and service advantage may be achieved in a more concentrated way, more quickly and with greater impact as part of a footprint reshape than through retrofit in a sub-optimal model

Affordability

- How will transition be funded and what prioritisation is required? A balanced-risk business case and plan are needed

- Parallel effort to drive out non-value-add activity, reduce working capital and target efficiencies in the current model will create additional headroom to manoeuvre

Having dealt with the immediate threat from COVID-19, executives, stakeholders and shareholders are now turning their attention to what comes next.

Businesses that are proactively considering the options now will be better placed to make the right moves to sustain and grow.

How we can help

We have broad experience of working with industrial clients to deliver higher levels of profitability and resilience by optimising the cost base, with managed risk and without compromising business value-add service delivery.

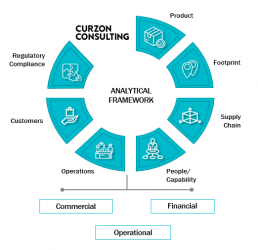

Our bespoke Assessment Model is a tried and tested approach balancing commercial, financial and operational considerations. We can rapidly examine the possibilities, frame the options and quantify the associated benefits and risks to underpin confident decision-making.

We bring a business-led focus, an insight-driven approach and a pragmatic attitude to help our clients make informed decisions. And where needed we assist in delivering the business case.

Contact us to explore how to deliver a more resilient and cost optimised business in a post-COVID environment.

Want to find out how our Industry & Energy Services consulting team can help?

Digitalisation in building supplies

The global COVID-19 pandemic is changing customer behaviour across the UK. We explore the digitalisation adopted by many building supplies companies to meet new customer expectations.

Muhammad Ali, Curzon Consulting Principal, discusses the impact of coronavirus on customer expectations and digitalisation with David Young, Group CEO of The Bradfords Group. Bradfords is a leading independent Builders Merchants in the UK.

Watch the highlights of our conversation:

Changing customer expectations

Navigating supply and demand challenges brought about by COVID-19

David explains the challenges that the pandemic has created in the building supplies industry.

Initially, Bradfords’ shops remained open to support essential projects and self-employed customers. In March, the morning after the UK lockdown was announced, Bradfords experienced extraordinary levels of demand. They realised that although Bradfords had a number of social distancing measures in place, they wanted to create a new process to safely meet the rapid change in customer demand. They opened back up the next morning with a brand new process – to order either via phone and collect, or order through the website.

This generated “unprecedented demand on the phones”, increasing from around 1,500 calls per day to 15,000. Consequently, both trade and retail customers looked to other channels such as the website. David explains

“we started seeing a big uptick in our trade customers using our portal and then transacting online, and also retail customers”.

However this surge in online demand came with a new set of supply chain challenges. Therefore, to ensure that Bradfords could continue to supply products for essential products and key projects they:

- Temporarily closed their business to the retail customer base

- Rationalised their product range

Furthermore, showcasing fewer products created a better website user experience which in turn generated an increase in sales. In fact, the eCommerce sales are still increasing, even now Bradfords have reopened their shops and yard to customers.

Are these changes in customer behaviour expected to continue?

In the short to medium term, this changing end user behaviour is expected to continue. Trends include:

- Customers increasingly plan ahead

- Customers continue to buy online

- An increase in retail customers

- A spread of footfall across the day, rather than a concentration of customers in the morning

“What COVID-19 has forced customers to do is plan ahead” David Young explains. Due to extended lead times and the click & collect service, Bradfords have seen their customers become much more planned. This change in behaviour is also helping operations “it helps us manage our workloads and forecasting stock levels”.

Building a strong ecommerce offering

The growing focus on ecommerce in building products is mirrored in the wider UK retail market and high street. Companies like Bradfords have been “through a long journey on ecommerce” and now find themselves well positioned to generate new sales through this channel. This represents a shift in focus for the building materials industry. A renewed focus on driving sales through the website highlights the importance of understanding insights from data. David recognises that good data is an important investment and Bradfords work closely with suppliers to ensure they are capturing data.

Overall, the pandemic has led to a renewed focus on digital strategy.

“I think the pandemic has really forced people and businesses to really look at their digital platforms”.

What does the future of trade counter operations look like?

Digitalisation in building supplies merchants during coronavirus has caused a spread in footfall across the day in shops. David forsees that click and collect will become a bigger part of building merchant life, likely as a separate service. Offering click and collect on light and heavy side products, such as forklifts, will require companies to restructure the way they operate. Key considerations are:

- Resource to ensure they can offer customers quick turnaround time

- Speed and efficiency of processes

- Omni channel offering

- Flexibility around opening hours – digitalisation opens up a 24 hour service

- Product ranges

The ability to react quickly to meet changing demand is key, both within the business and across the supply chain. Indeed, David recognises the importance of planning ahead and sees the importance of builders merchants becoming “much more productive in the future”.

Changing relationships across the supply chain

Will digitalisation disrupt the value chain? Does it change the relationship between manufacturer, distributor and end user?

David sees this as an evolution rather than disruption:

“I think the relationship between the merchant, and the supplier will change dramatically. You know data is so important and historically I’ve found that data within our supply chain is very poor… a lot of manufacturers just don’t hold the level of data needed in this new world…

I think there’s a big wakeup call coming”.

Merchants need to be mindful of potential risks, particularly if they:

- Are slow to react to digital customer demand and develop their eCommerce platforms

- Don’t react quickly – “actually some of the suppliers will vertically integrate and sell direct and cut us out.”

This evolution also presents a number of opportunities for building supplies merchants to:

- Work with suppliers that are invested in data and technology

- Build stronger vendor relationships

- Attract a new demographic of customer

- Understand the many payment platforms and react accordingly

In summary, digitalisation across building supplies gives businesses the opportunity to adopt digital, improve customer experience and improve supply chain relationships.

Contact us

Contact us to discuss how digital strategy, transformation and customer experience can be applied in your organisation.

We can help your organisation with digital strategy, transformation and customer experience.

Want to find out how our Industry & Energy Services consulting team can help?

Curzon becomes ADS member

Curzon Consulting becomes a member of the ADS Group, a trade organisation for UK companies across the Aerospace, Defence, Security and Space sectors.

Curzon Consulting Partner, John Mason, commented:

“Joining ADS keeps us close to the issues that matter most to this critically important UK industry. We have worked with clients in the sector providing help with a range of management challenges to build stronger businesses. We look forward to working with ADS and member firms, developing our knowledge, capabilities and service offers further and continuing to support the aerospace and defence sector.”

How we help UK businesses across aerospace and defence

We work with clients in the aerospace defence sector to deliver step-change performance improvement, bringing broad industry experience and a strong business-results orientation. Our capabilities include transformation strategy and digital evolution, operating model re-shaping, and operations and supply chain excellence through data-driven decision making.

CONTACT US TO FIND OUT HOW WE CAN HELP

Performance turnaround at global construction product manufacturing group

The issue

- A European headquartered global construction product manufacturing & distribution group with a C. and S. American Division located across 14 countries

- The Division was consistently the worst performing business unit in the Group

- Interventions from Europe had failed to address the issues and turn performance around

- Performance was poor with an EBITDA generation significantly lower than the Group average

- Underperformance was a consequence of a multitude of issues: poor sales disciplines, inefficient production, lack of adequate cost management and ineffective leadership

- Previous attempts to turn the business around with other consultancies had failed

- The challenge was not only to quickly improve performance, but to set up the business for sustainable profitable growth

What we did

- With our Alliance Partner for C. and S. America, Curzon established a programme team to implement a comprehensive change effort

- A focus on commercial performance including pricing management and product mix optimised the market opportunities and stopped margin give-away

- Introduction of lean practices in manufacturing and distribution facilities improved productivity and started to tackle excess inventories

- Organisational changes were made to reduce management overheads and to streamline support functions

- Initiatives were piloted in country businesses and the learning was transferred to other business units through a centrally managed process to coordinate and accelerate the impact

The results

- Within one year the division rose from the worst to the best performer in the Group

- The combination of programme and other initiatives were delivering measurable bottom-line savings with a headline profitability run-rate that had tripled

- Change was happening on a broad base and over 1000 staff across multiple countries were involved improving the business

- Capability development and introduction of new tools, disciplines and ways of working had provided a solid platform to sustain the results

An award-winning team

CONTACT US TO FIND OUT HOW WE CAN HELP

Increased operating profit at glass manufacturer

The issue

- Our client, a manufacturing site for automotive glass had struggled to break-even through four years of plummeting demand

- The site’s future was in doubt unless it could quickly demonstrate growth in efficiency and competitiveness

- Cultural resistance to change

- Strain on production teams

What we did

- Operational analysis identifying where, why & how greater efficiencies were achievable

- Designing & managing transformation pilot, measuring effectiveness

- Prioritised roll-out, training & robust project governance

- Worked with management to embed leadership skills & capabilities

The results

- Our work delivered benefits exceeding €10m annualised operating profit & €20m working capital reduction

- We helped our client become a Group-wide exemplar of best operating practices and re-establish its position as a market leading producer

- The transfer of crucial capabilities to the local team has enabled sustainable change

- San Salvo is now a credible, long term engine of growth

- Our work was awarded “Highly Commended” at the MCA Awards for Change Management in the Private Sector

€10m

annualised operating profit

€20m

working capital reduction

What our clients say

“As a result of Curzon’s support a strategic and digital leap has been made in how we manage the entire asset lifecycle to transform our Developer Service experience. This is a programme and a product that sets a new benchmark within the industry.”

Jason Tucker

Director of Alliances & Integrated Supply Chain, Anglian Water

An award-winning team

CONTACT US TO FIND OUT HOW WE CAN HELP

Delivering a step change in operational performance

The issue

- Four factories on one site producing 60% of the company’s European demand for the Automotive market

- Utilisation and performance had been in steady decline for four years and with very poor customer delivery and service performance this was seen to be a failing site

- Local custom and practice was inhibiting opportunities to improve productivity

- Curzon was engaged to help the Site Director achieve control and turn performance around

- The site was achieving less than 60% OEE on its premium integrated lines

- High inventories but of the wrong products due to lack of control of demand and production priorities

- No performance management system in place to drive improvement

- Disconnected Planning and Production functions causing late delivery and high costs

- Limited management capability and lack of proactive supervision

What we did

- Create an overall approach to transform the performance of the site involving all of the management team

- Implement a cross-functional planning process and tools e.g. production wheels to establish a clear view of demand, delivery priorities and factory capability to deliver

- Implement Lean capabilities on the shop floor e.g. SMED techniques, SIC and Kaizen to improve productivity and develop a sense of ownership

- Selective capital investment in facilities (underway)

- Implement visual performance management and supporting proactive supervisory/management processes

- Build the capability of the local team to ensure sustainability

The results

- Achieved in excess of 25% reduction in inventories and a significant uplift in on time delivery to distribution centres

- Improved OEE on key integrated lines by over 20%, increasing capacity and enabling transfer of work from less productive sites

- Built the capability of the client team to be able to complete the programme rollout successfully themselves and to sustain the initial improvements

- Created a blueprint that can be rolled-out to other sites globally

25M

reduction in inventories

20%

increasing capacity

What our clients say

“As a result of Curzon’s support a strategic and digital leap has been made in how we manage the entire asset lifecycle to transform our Developer Service experience. This is a programme and a product that sets a new benchmark within the industry.”

Jason Tucker

Director of Alliances & Integrated Supply Chain, Anglian Water

An award-winning team

CONTACT US TO FIND OUT HOW WE CAN HELP

Extracting value from data analytics in manufacturing

In an article published in Raconteur’s “Future of Manufacturing’, John Mason discusses how manufacturing firms have turned to data analytics and artificial intelligence and asks how many are failing to reap the rewards. What is needed is a sharper business focus to achieve expected returns.

Aside from the high-tech and leading corporates, adoption of digital technologies in the manufacturing sector remains subdued, a consequence perhaps of not seeing widespread evidence of the tangible benefits. Achieving expected returns on investment from advanced analytics and AI is less a question of technology and more a business challenge.

Success stories among early adopters are well publicised and demonstrate the advantages to be gained when the power of data from multiple sources is harnessed through expert hands and into business execution.

More precision in research and development reduces costs and increases success, product lead times can be compressed, sales and service are optimised for overall value, goods can become services, supply chain efficiencies are maximised, defects are reduced and production assets can operate at their potential.

For many though, there are “missing links” that are preventing the expected value being realised from the potential a wealth of data, analytical skills and technology are offering.

Clarity of business priorities is the starting point and that requires executive level direction. Technology has provided the toolkit, but how it should be used to best effect cannot be delegated to the IT function. The increasing presence of chief digital officers on executive teams is one trend bridging the gap between the business agenda and the role of technology.

“Generating business insight is a critical business capability that unlocks new value yet sometimes seems to be forgotten among the increasing volume of information and analysis,” explains John Mason.

Advanced analytics enable businesses to combine multiple datasets to highlight new information. The same cross-functional thinking is required in the application of this information.

For example, optimising asset performance will require co-ordinated action across production, engineering, maintenance and third-party equipment suppliers to achieve the potential performance uplift that connectivity and predictive analytics can offer. Most importantly, the business and IT functions need to work much more closely, and find a common language.

Risks associated with data security are often cited as a brake on adoption. Having a robust governance framework that defines who owns what information and how it should be used is essential.

50%

initiatives don't deliver their cost of capital

67%

companies reported human and technical capabilities as a bottleneck

Arguably the least considered aspect of a technology-led investment in data and analytics is the practicality of turning insights into measurable results. Success requires organisations to have the capabilities to act on and implement changes. The ability to test, learn, adapt and adopt is needed at all levels, and information needs to be made available to those who are going to use it in a way that is practical. Implementing minimum viable products and adopting “fast-fail” approaches that can quickly demonstrate impact are not widely established practices in many organisations.

Operating models and processes need to be capable of accommodating evolving knowledge, and the perceived threat that time-served, experienced staff may feel need to be overcome. “The expectation that the whole organisation will automatically see the benefits is likely to be unfulfilled. Involvement and ownership are key, as they are for any sustainable business change to work,” says Mr Mason.

When the links are forged for businesses to generate genuine commercial insight and swiftly translate it into action, the potential advantage of analytics will be fully realised.

This article originally featured in Raconteur, August 2018

About the author

John Mason

I lead our Manufacturing practice helping clients tackle complex business challenges to achieve a step-change in outcomes, whether it be re-shaping for growth, accelerating performance improvement, or leveraging the possibilities offered by digital and automation technologies in a time of rapid evolution.

CONTACT US TO FIND OUT HOW WE CAN HELP

Unlocking hidden capacity in manufacturing

Regardless of the scale or nature of your operations, hidden capacity in manufacturing can be found far more often than you might think.

Curzon Manufacturing sector lead John Mason explains key considerations for manufacturers.

In our experience, even operations that appear to be performing well are often far from efficient. In fact, these inefficiencies have crept in over-time and become accepted and invisible. Requests for more and more capital to deliver capacity increases. High levels of unproductive inventory are the common symptoms that executives see.

One of our clients, a world-leading glass product manufacturer, was suffering from low productivity at their largest European production site and increasing their stockholding to cover poor performance. We worked with them to maximise their production capacity, allowing them to service additional demand. As a result our client achieved a multi million pound increase in operating profit, while simultaneously reducing working capital by 35%.

What can you do to identify hidden manufacturing capacity and locked-up cash?

Challenge your operating envelope. Are plant and people operating together at their maximum, and how do you know? Improvements to equipment and ways of working will have been made over time but often there is no systematic capture and re-setting of new standards. Plate capacity is probably out of date.

Plan for success.

How much output is being lost through sub-optimal routing and low-efficiency changeovers; and are long production runs the best answer to avoid these losses? Has the best sequence been worked out to balance the need to meet customer demand and to minimise lost productive time, and when the planning is right, how good is schedule adherence to the plan? Getting it wrong will hit capacity or tie up cash in excess inventories. Or probably both.

Measures matter. Plants that appear to be performing well might not be. Have you got a handle on true performance with consistently applied definitions and accurate reporting? Are you incentivising the wrong behaviours through driving cost recovery? Carrying high levels of the wrong inventory is often an unwanted consequence of an unmanaged drive for lower unit cost.

Manufacturing is a science, not an art.

Are processes under control? How quickly and routinely does a plant establish maximum throughput of quality product at start-up, and does it stay there? To what extent is there acceptance of variability and reliance on experience and judgement to ‘coax’ the process rather than repeatable and reliable operations? For instance, focusing on Overall Equipment Effectiveness (OEE) to achieve a 2% increase in capacity on a continuous chemical products plant returned a multi-£m profitability uplift.

Eliminate non-productive time.

What is dictating throughput rate? A precision engineering client was achieving just 3% velocity through their process; a huge opportunity to compress cycle times and slash work-in-progress inventories. Are improvement efforts focusing too much on increasing the output of a single stage or machine rather than looking at the system as a whole? We helped another client to halve the throughput time of their precious metals processing activities by eliminating built-in wait time between stages and achieve a 12% increase in their return on assets.

Don’t overlook maintenance.

A plant that isn’t running is lost capacity and poor maintenance operations are often a cause. How effectively are you organising, skilling and utilising all your resources to look after your assets? Having your operators carry out standard routines for example will improve reliability and free up engineer time. Have you got the right asset strategies, information and service provision to maintain plant availability in the most cost-effective way?

Empower your team.

Manufacturing companies are reliant on front line staff for day-to-day efficient use of scarce resources. How well do your people see the opportunities to improve, how equipped are they to unlock the potential and how appropriately are they recognised for their efforts? These questions are not for Human Resources to answer. One of the biggest levers you can pull is effective engagement and development of your operational staff.

Unlocking additional capacity in manufacturing to create value isn’t just the job of Operations:

Look beyond the factory floor. What impact are other functions having on the ability of Operations to maximise their effective use of capacity? How much stoppage, rework and yield loss is as a consequence of the extended value chain? How effective are the interfaces and relationships between Operations, R&D, Engineering, and Commercial functions? We discovered with a capital equipment engineering firm that the root cause of poor performance and lost capacity in the factory stemmed from poor management in the Design Engineering function.

Customer first, but not at any cost.

Manufacturing companies’ sales teams may want the warehouse full of stock to maintain the highest service levels. But what are customers actually prepared to pay for? Is the available capacity being used to generate the most profitable returns or to just build buffers to mask performance of an ineffective supply chain? Sometimes the results are surprising. One such review uncovered the value-destruction of actively migrating customers to a new, ‘better’ product… with a lower margin.

More capital spending isn’t always the answer.

Often the accepted wisdom is that capital is needed to create additional capacity. Have all the alternatives been looked at before committing? How far can improved leadership and good practice operating disciplines take you first? We helped a specialty chemicals producer avoid a multi-million and multi-year plant build when the capacity already existed to meet their needs by optimising the product mix and de-bottlenecking the plant.

About the author

Get in touch to find out how we can help unlock capacity in manufacturing companies.