Abhishek Roy

Consultant

44 (0)7459 047 273

Abhishek is a Specialist Physician turned Management Consultant, with over 7 years of work experience in the public healthcare sector in India. He has successfully led large teams across geographies amidst highly complex and challenging environments of COVID and paediatric epidemic crises.

He holds a Bachelor of Medicine and Surgery (MBBS) and a Doctor of Medicine (MD) in Clinical Biochemistry from prestigious medical schools in India. He also holds an MBA from Saïd Business School, University of Oxford, with concentrations in Strategy, Technology, and Entrepreneurship.

In addition to his medical work, he has also juggled being an Entrepreneur and Strategy Consultant to health-tech start-ups in an accelerator programme. Combining his previous experience in healthcare and his business acumen, his vision is to help solve the most complex problems plaguing the healthcare industry across the world.

CONTACT US TO FIND OUT HOW WE CAN HELP

Business performance turnaround for a multi-country division of a global building products group

The issue

- LATAM division of a €3bn global construction product manufacturing & distribution group

- Country-based business units in 14 geographies from Mexico to Chile with 3,500 staff generating revenues of €400m

- A sustained period of under-performance with operating margins at sub-3% making it the worst-performing division in the Group

- Divisional layer not adding any value with local businesses being left to operate independently, some with more success than others

- An extended analytical diagnostic by a global consulting firm had established the scale of the problem, but no credible and accepted plan to address the issues had emerged

- The need was for pragmatic help to make change happen with the full buy-in of local management

Solution

Plan and mobilise stage

- Confirm the scale of the improvement opportunity

- Agree targets and align with budgets to have one set of numbers

- Create a plan and a governance model to balance top-down coordination with full engagement from the business units

Delivery stage

- Initial focus on four of the largest markets where impact potential was greatest

- Reduction in margin leakage through pricing optimisation, product mix & discount control

- Introduction of operational excellence basics across manufacturing facilities

- Inventory optimisation, including clean-up of obsolete and slow-movers

- Reduction of corporate overhead layer and leverage of shared service centre to reduce in-country costs

- Capability development of management and teams across all disciplines

The results

- The Division was transformed from worst to best performer in the Group within 12 months

- Operating margin tripled and accrued benefits delivered were 45% above the programme target

- Working capital was reduced by €25m

- The change management effort involved over 1,000 staff across all functions and businesses

- Awarded ‘Best International Project’ by the UK Management Consultancies Association

- Curzon entered a risk-reward commercial arrangement on benefits delivered

We wanted a step change in performance, done in a way that would build capability to make it sustainable… the results speak for themselves. – Divisional CEO

An award-winning team

CONTACT US TO FIND OUT HOW WE CAN HELP

Congratulations to Our 2021 MCA Awards finalists

We are delighted to announce that Curzon Consulting are finalists in 2 categories of the Management Consulting Awards 2021, representing the very best of our consulting business.

Established by the Management Consultancies Association, the #MCAAwards demonstrate the transformational work the sector has undertaken during the last challenging twelve months.

2021 marks the seventh consecutive year that Curzon Consulting has been finalists at the prestigious awards.

Commercial Excellence

Curzon with AIG – ‘Back to Life’ – Fast-Tracking to Leadership in Customer & Profit Retention

Read More

After a period of impressive top-line growth, AIG Life’s leadership now concentrated on driving for profitability on a US GAAP basis. Working with Curzon to isolate what could best deliver profit uplift, we zoomed in on a stubbornly un-moving customer persistency rate and recognised that every 1% point of lapse averted would yield significant and multiplicative profit gains.

Curzon was engaged on an ambitious programme to rapidly get control of lapse and release commercial benefit, and to build the capability to achieve best practice retention management. This was an enormous challenge given the starting point: no set persistency strategy, an absence of key lapse analytics, retention not owned or resourced in the organisation, and a lack of lapse prevention and turnaround processes.

Over 11 months through 2019, we took a pragmatic, agile, and ‘together’ approach to accelerate to retention excellence, securing the organisation’s buy-in to what it would take to get there, and quickly demonstrating the commercial, operational and customer benefits of joined-up retention management. Curzon enabled the new cross-functional working essential for success, and gave the business the structures and confidence to operate highly effective preventative and save processes – internally and leveraging external partners.

Among the prime watershed moments were revealing how:

- a shift in distribution mix from advised face-to-face to telesales had created a hitherto unseen problem of drop-out inside first 3 months

- customer communications from welcome onwards needed to explain clearly the personal value of life insurance, and how holding it ensures financial provision for those you love

- rather than automatically cancelling customers on request, customer service had a responsibility to engage them before they make a potentially uninformed decision

When the business took the reins 3 months after improvements were implemented, lapse rate had been reduced to the best practice % mark on a run-rate basis and incremental revenue and profit benefit unlock was exceeding our original target. This translated annualised into 5-figure policy saves and a cumulative £multi-million gain in Pre-Tax Operating Income by 2023. The business had taken ownership of a new retention management function, with a new Lapse MI suite providing the predictive insights to continually optimise retention. Beyond achieving the agreed objectives, the work also led to complementary projects including work to minimise drop-out in the Bank partnership sales channel.

Commenting on the success, AIG Life CFO Donald MacLean said:

“Curzon helped us obtain the confidence and operational ‘can-do’ to get control of lapse sooner than we could have expected, and then to push on to best practice performance.

As always, their skill was in balancing pace of change and the results imperative with the need to take the organisation with them on the journey. A key achievement was building the necessary collaboration between the many functions that needed to act together to manage retention in a joined-up way.

The result was a tangible and ongoing commercial win, and a vital new balance struck between sales and retention for business profitability and sustainability”

People

Curzon with Highways England – ‘Project Performance Accelerator – Enhancing delivery capabilities through innovative approaches and working relationships to achieve HE delivery goals

Read More

Project Performance Accelerator (PPA) was designed to develop and implement a delivery mechanism for Highways England’s (HE) overarching Business Transformation Programme, addressing inconsistent levels of capability throughout HE’s Project Management community and developing highly skilled project delivery teams. Overall, HE’s three main Major Project programmes account for 80 projects worth more than £23bn, each being delivered by a supply chain or contractor led by a Project Management team.

PPA’s leader Steph Illingworth engaged Curzon to interpret and structure her Vision of the PPA Programme into clear deliverables, shaping the fundamentals. There was consensus on cultural flaws and ineffective ways of working. Revealing a deeply siloed organisation with multiple departments or technical areas that lacked collaboration or a holistic view of the primary objectives and deliverables: projects were not executed on time and within budget, nor maximising benefits and social value. Also, capability development and training programmes were too theoretical and onerous, focusing on processes and systems rather than people, impacting the overall project success.

Focusing on performance management, capability development, project control capability and enhancing commercial acumen, the PPA Programme included two outputs as the medium for change: An Immersive Learning Experience and Digital Project Management Guidebook.

The Immersive Learning experience was designed to disrupt the way programmes are delivered. The Digital Project Management Guidebook contained PM content selected through independent reviews and capability assessments. Both outputs were crafted around the project lifecycle of typical HE infrastructure projects, set to be delivered in-person over a period of 18 months. Cohorts were selected to receive a tailored experience, improve project team maturity, and provide a solid foundation for capability uplift to achieve clear learning outcomes and benefits.

At the heart of the PPA philosophy was to enable project teams to grow, enhancing ‘ways of working’ whilst bolstering project performance. These included a “working better together model”; a fundamental shift in the way individuals interact and take ownership of overlapping project aspects and problem-solving techniques. This, along with the Immersive Learning, reinforced the Programme’s success, shifting the focus from systems and processes to people.

The pandemic introduced significant challenges, necessitating the immediate conversion of the Programme from in-person workshops to a virtual setting. The team adapted structures and materials, incorporating a variety of software suites to enhance the learner experience. Frequent interaction and close collaboration with the internal and senior stakeholders were critical to maintaining speed and delivery, adopting a fail-fast, fix fast approach to syllabus creation

The consulting team could interpret the client’s vision into a clear pathway, support and enhance the design to become one of the most successful transformation project delivered in HE.

The Digital Project Management Guidebook launched in August 2020 via four interactive webinars to c.300 employees have now received over 1,000 unique viewers. A modified deployment strategy was adopted in light of the pandemic, redesigned as a remote Immersive Learning Experience. However, over 5,049 hours of remote learning have been received by 100 staff through 9 project teams, enhancing teams’ capability with a combined portfolio value greater than £3.3bn.

Congratulations to all of the other finalists.

CONTACT US TO FIND OUT HOW WE CAN HELP

Curzon Consulting partner is Category Judge for 2021 Soldiering On Awards

2021 Soldiering On Awards

Curzon Consulting Partner, Douglas Badham, is proud to again be a Category Judge for the 2021 Soldiering On Awards.

The Soldiering On Awards highlights the outstanding achievements of current and former service men and women, their families and those who support the Armed Forces Community. Now in their eleventh year, the Awards recognise inspirational people for achievements in education, healthcare, communities, diversity and inclusion, and business.

Douglas said:

“This is my second year of judging and I am an ardent supporter of the Awards – for the past eleven years these awards have shone a light on inspirational stories of immense challenges overcome, and stunning personal and business achievements”

Despite the challenges of a pandemic, the Awards have received a record number of nominations.

Lt. Col. Ren Kapur MBE, Founder and CEO of X-Forces Enterprise CIC and Co-chair of the Soldiering On Awards said:

“In what has been another record-breaking year for the number of nominations received, my thanks go to our category judges for the diligence and dedication they have applied to this important step on the path to decide who will be the 2021 SOA Finalists.”

The Finalists will be announced during Armed Forces Week in June.

For more information

About the author

CONTACT US TO FIND OUT HOW WE CAN HELP

Building capabilities for customer centric decision-making using time to value

In our latest blog post relating to Intelligent CX, Curzon Analyst Milla Bradstock explores how to build capabilities for customer centric decision-making using Time to Value.

Time to Value, as a metric, initially rose to fame among software companies and its insights now drive improvements in a range of business contexts. In a customer context, it is described as the length of time between a customer purchasing a product or service and seeing the value of that action. Yet to untap the metric’s full potential, businesses must take a longer-term view of its application that goes beyond resolving customers’ immediate needs.

As T2V requires organisations to understand the value of their product or service from a customer’s perspective, it entrenches customer-centricity into the way businesses think about their services. At a time of rapidly shifting customer priorities, organisations that take this approach will be well placed to remain aligned to the needs of their customers.

Measuring Time to Customer Value

Tracking T2V builds a picture of your present customer journey, which will inform solutions to better fulfil customer needs. However, you can only track T2V if you know what ‘value’ is in the eyes of your customer. The definition of value will, of course, differ amongst your customers, but we can start to break down this metric into two sub metrics:

-

Time to Basic Value – The time it takes for a customer to see the minimum amount of value from your product or service. Delivering on this metric doesn’t lead to customer loyalty necessarily, but will increase conversion.

-

Time to Exceeded Value – The time it takes for a customer to see enough value to exceed their expectations over a longer period of time. Delivering on this metric reduces churn, builds loyalty and increases customer lifetime value.

For example: A travel app with an easy to use interface and intuitive search results will deliver on the Time to Basic Value metric. However, its Exceeded Value will be realised only when it helps a customer have a good holiday i.e. booking a place to stay using the platform.

T2V helps businesses identify obstacles to customer satisfaction, which inform solutions for long-term value creation in the eyes of their customer. For SaaS businesses, onboarding is essential to their customers seeing value from their purchase, which creates the challenge of motivating customers to complete the process.

Focusing on accelerating T2V at this point in the customer journey can therefore decrease customer churn and improve satisfaction. Automated onboarding can be an effective tool, delivering frictionless setup and easy deployment through product tours, in-app messages and onboarding checklists. In tune with customer demands for instant service and ultimate convenience, this tool enables customers to seamlessly see the value of their purchase for themselves.

Implications for organisations

- Move the narrative from Customer Needs to Customer Value

- Focus on Customer Engagement beyond the initial purchase

- Measure and monitor customer engagement throughout the Customer Lifecycle

- And, of course, ensure the engagement delights the customer every time

How we can help

T2V is just one of the tools that we employ to help our clients improve customer value. Businesses that invest now in strengthening their capabilities for meaningful customer engagement will build the resilience necessary for long-term success.

Get in touch to explore how we can help your organisation create lasting value for your customers.

Rachna Trehan leads Curzon Consulting’s Intelligent CX practice. Connect with Rachna on LinkedIn or contact her to discuss how this could apply to your organisation.

Other members of the Intelligent CX team

CONTACT US TO FIND OUT HOW WE CAN HELP

UK’s Leading Management Consultants 2021

Ranked in the Top 20 of the UK’s consulting firms, we are delighted to have been recognised for the third consecutive year as one of the ‘UK’s Leading Management Consultants 2021’ by the Financial Times.

Recommended in seven categories compiled with data company Statista, the annual rating is based on endorsements by clients and peers and demonstrates our steady consistent year on year sector & service line growth.

Consulting companies are awarded Bronze (recommended), Silver (frequently recommended) or Gold (very frequently recommended).

Sectoral expertise

- Construction & Infrastructure – Silver

- Financial Services – Bronze

- Healthcare – Bronze

- Public & Social Sector – Bronze

Consulting services

- Digital Transformation – Bronze

- Operations & Supply Chain – Bronze

- Strategy – Silver

Managing Partner Andrew Morgan said

We are thrilled to see the continued progression of the firm, competing alongside some major consulting brands. I am really proud of the team and this reinforces their dedication to deliver tangible results for our clients in a range of markets through strategic, operational and transformational delivery.

CONTACT US TO FIND OUT HOW WE CAN HELP

Future of work: healthcare med reps transformation

In his latest blog post relating to Future of Work, Curzon’s Managing Consultant Rodrigo Quezada Dighero focuses on the transformation of healthcare medical sales reps.

Exploring how the pandemic has disrupted the face-to-face salesforce, and the unique opportunity this presents to adapt the operating model for future success.

The effectiveness of a disrupted salesforce

One year into the pandemic and face-to-face sales look very different from 12 months ago. Medical Reps are facing exceptional challenges in reaching their sales targets, as restrictions on in-person meetings with HCPs continue.

The gravity of the situation is reflected in the 16 new drugs launched during COVID-19 lockdowns, that are at risk of sales failures, according to one pharma consulting group.

However, the lifting of lockdowns is unlikely to return the industry back to ‘normal’. In fact, the evidence shows a stark reality for in-person sales.

-

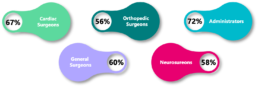

About 60% of surgeons believe that restrictions on in-person sales are likely to remain even after a Covid-19 vaccine is available and lockdown restrictions abate.

Percentage who believe restrictions on face-to-face visits are likely to continue after Covid-19

Moreover, the changing landscape is not just a result of the pandemic; it’s expedited the necessary changes, but fundamentally, companies have been very slow to adapt their operating models to address the needs and wants of their customers and workforce.

-

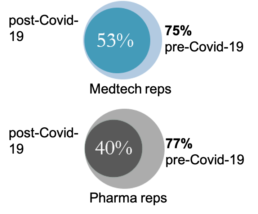

Of the 75% of physicians who preferred in-person visits from Medtech representatives prior to Covid-19, 47% would now opt for a virtual exchange or less-frequent visits.

-

Many physicians once sceptical of any virtual interaction with sales reps now report these exchanges are high quality and offer a much better experience.

Healthcare providers are demanding more from pharma, as they seek greater value from their interactions with Med Reps.

-

69% of doctors now want digital patient education

-

67% want more education on remote patient care

-

65% need specific information on conditions relative to COVID-19

-

65% require information to help patients access labs, tests and imaging

It’s clear as medical professionals endure the uncertainty caused by COVID-19, changes are here to stay, and adaptation is crucial to success.

Identifying the opportunity - a new way of working

Digitalisation has accelerated the Next Normal requiring pharma operating models to adapt, or in some cases, completely transform to help them to thrive or even survive.

In this context, the need to provide refined, enriched collateral to healthcare providers and doctors demands an evolution from face-to-face meetings and conferences into a hybrid exchange of virtual and in-person meetings, steered by medical reps.

Percentages of doctors who prefer in-person sales visits

However, in order for this to be fully realised, pharma companies need to adjust and develop their salesforce capabilities. In another study, research shows that only 26% of pharma reps get coaching personalised to their needs. A focus on sales coaching, through integrated, personalised and value-driven interactions will support med reps to identify target prospects and align the products to the needs of the HPC, through their preferred communication channel.

Moreover, managers and leaders need to align sales & marketing, to ensure a collaborative approach to fully understand the customers and the local market they operate in. Communication and insight must flow both ways to drive communication strategies, content creation and support product development.

Our approach

Our approach to New Ways of Working accelerates the adaptation to the digital business model, focusing on the delivery of required capabilities and the evolution towards a hybrid model.

For this specific transformation, we focus on four of the five key areas

-

Organisation

-

Collaboration and Hybrid Solutions

-

Smartworking Processes

-

People & Leadership

Organisation

- Develop strategies that assist medical reps throughout the sales process, tailored to every customer touchpoint.

- Establish hybrid teams that can develop relevant, channel-specific, timely content to empower the med reps.

- Foster internal engagement and alignment by creating a purpose-based organisation with a relentless focus on value-add customer service.

- Entrench company culture to sustain new ways of working and improve business agility – always listening… constantly evolving.

Collaboration & Hybrid Solutions

The virtual nature of teams and work communities spearheads the need to adopt solutions that enhance and facilitate effective remote interactions.

- Optimise team relationships, roles & interactions to enhance hybrid ways of working.

- Design and implement collaboration solutions applied to the business and team leadership.

- Adopt collaborative tools, enabling sales & marketing teams to share opportunities that improve the quality of exchanges, content creation and value-based interactions regardless of location.

Smartworking Processes

Achieving process transformation through re-engineering & automation to create a generation of agile, flexible, efficient and collaborative working dynamics.

- Redesign smartworking processes, harnessing automation and flexibility to accelerate change and bring the hybrid model alive.

- Employ digital tools to evolve sales, HCP engagement and bring the customer experience to the forefront of every interaction.

- Remove silos to cultivate employee engagement and shared knowledge/opportunities.

People & Leadership

Evolution of culture and people is the foundation of Digital Transformation enabling leaders of pharma companies to steer a change in behaviour and actions.

- Adapt the hybrid model and embed culture based on learning and sharing.

- Develop salesforce capabilities with a focus on digital skills, converging efforts to support sales requirements through content creation and content sharing.

- Embed a coaching culture that fosters learning and sharing.

- Deploy cultural change that embraces and cements the New Normal.

The time to act is now

We work with pharma businesses to deliver New Ways of Working that accelerate the adaptation to the digital business model. Ultimately our work helps businesses to grow, improve customer retention and discover new opportunities.

Ask us how we can help your organisation to transition into the New Ways of Working putting your salesforce ahead of the curve.

CONTACT US TO FIND OUT HOW WE CAN HELP

Future of Work insights

Diane Tibbles

Marketing Manager

+44 (0)1653 628596

Diane is a highly motivated and driven CIM qualified senior marketeer with over 20 years’ experience, she has built her career in a variety of industries in both stand-alone, managerial, and consultative positions.

She is confident, tenacious, and adaptable with a proven track record of delivering first-class marketing management and stakeholder satisfaction. With skills and experience that cover all areas of marketing, she has a solid reputation as a visionary problem-solver and creative tactician to deliver marketing strategies and positively implement direction and change. An excellent communicator and leader recognised for building, leading, and training high performing teams.

“I love to read; I am a hoarder of information, which feeds my thirst for learning, ensuring that if I don’t know the immediate answer, I will make it my mission to find it.”

CONTACT US TO FIND OUT HOW WE CAN HELP

Lean value chain analysis and design for global precision engineering products leader in aerospace industry

The issue

- A complex multi-stage casting, machining and coating operation manufacturing precision components for the aerospace industry

- Underperforming organisation and low levels of ownership for improvement

- Extremely low velocity through the process, with poor yields and excessive scrap

- High inventories of work in progress and finished goods

- Production measures encouraging over-production

- Silo mentality in operations exacerbating the WIP situation

- Disaffected workforce with little interest in driving continuous improvement and no effective performance management in place

Solution

- Analyse the current situation to articulate the operational improvement potential (yield uplift and inventory reduction)

- Create the business case for change (P&L and cash impact)

- Design a pilot to create an integrated supply chain for the largest volume product including suppliers and JV partners

- Detail design of a pull model and elimination of WIP stages along the entire supply chain

- Re-design of the layout and organisation to separate ‘dirty’ and ‘clean’ operations to reduce rework

- Launch of a continuous improvement approach within the shop floor to tackle scrap, rework and productivity issues

- Design and introduction of a cascaded performance management framework

The results

- 40% reduction in inventory identified through WIP elimination

- The feasibility of a 50% reduction in production lead time confirmed

- 10 percentage-point improvement in yield performance from closer process control

- Plan to deliver £5m savings in-year agreed

- Changes to ways of working implemented in pilot cells with Lean work-flow approach trialled

- Programme of Lean training and continuous improvement projects implemented

- New KPIs are being used to drive the performance of the value chain in place of traditional cost absorption metrics

An award-winning team

CONTACT US TO FIND OUT HOW WE CAN HELP

Operating model refinement and commercial focus to deliver a step change in business performance

The issue

- A subsidiary of a global defence company, providing technology-based R&D solutions and advisory services to government and defence organisations and private sector companies at the cutting edge of secure communications and cyber warfare

- Despite repeated calls by Group to improve, the business continuously failed to meet performance expectations on revenue growth, profit margin and free cash flow

- The business was suffering from an overly-layered and siloed organisation structure, with burdensome management processes and lacking commercial focus

- The underlying issues were structural and an absence of effective performance management, wrongly being justified because business discipline would stifle creativity and innovation

Solution

- Undertook a business-wide design and business case development stage to anchor the current performance failings and the required changes

- Implemented over a 12-month period working alongside the business unit leadership with a structured plan;

- A new leadership team established, with stronger governance processes, metrics, and proactive staff engagement

- Simplified the operating model and aligned capabilities to market needs

- Re-framed value propositions and initiated the move into critical national infrastructure

- Implemented resource management to drive productivity uplift

- Implemented new mentoring and HR processes to underpin talent management

- Supported post-implementation by refreshing the plan

The results

- 29% revenue uplift (versus budget target)

- 18% Return on Sales achieved versus a 15% target for the financial year

- 90% improvement in business cash flow

- 10% points increase in Engineer productivity, with a continued increase to 74% utilisation in year 2, and climbing

- Transformed the operating model and business culture to be customer and commercially focused

- Established performance management at the business and individual level

- Underpinned changes with disciplines, governance, reward structures and visibility

- The Project won the Management Consultancy Association’s award for “Performance Improvement in the Private Sector” with full sponsorship of the client

An award-winning team